Last year, the administration granted the MSET’s First Robotics Competition (FRC) team permission to set up a 27-by-54 foot wooden game field to practice for the 2024 game, called Crescendo, in the school’s library.

The wooden structure occupied about a third of the usable space in the library from mid February till the end of May, but offered the team an opportunity to practice driving their robots and test their autonomous programs prior to a competition.

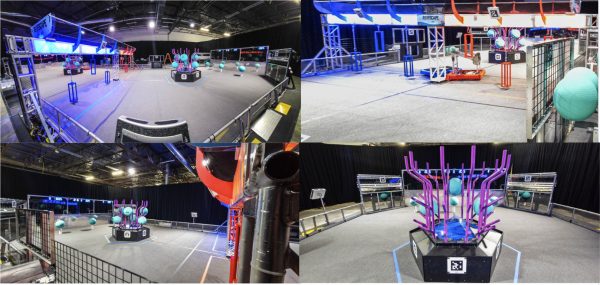

On Jan. 4, FRC revealed the 2025 game, REEFSCAPE, in which teams race to place “coral” PVC pipes on the “reef” in the center of the field while knocking off algae balls in their reefs and either shooting them into a net above the field or placing them in a trapdoor on the side of the field. In the final moments of the match, teams are awarded points if they can successfully hang on to a “barge” and elevate above the game field.

This year, the team will continue having space in the library until their season ends, which, in recent years, has been after the world competition in April. Currently, the team does not purchase fields from the official manufacturer. This has left the task of designing and constructing a practice field for the manufacturing team.

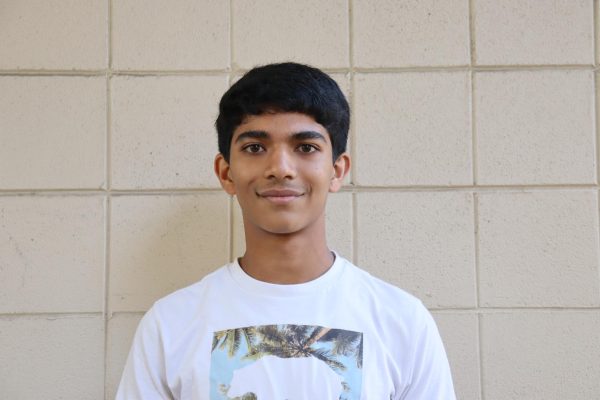

The driving team is composed of juniors Akash Gupta, Ishir Gupta and Ishaan Rao. Ishir and Rao are the team’s drivers while Akash is coach, guiding both of them during matches. As the robot continues to be built and modified, the team typically practices daily in the evening for about an hour. This number ramps up to 12 hours a week before competitions.

The manufacturing team, a subgroup within the FRC team, is in charge of developing and assembling a wooden game field with pinpoint accuracy to match the dimensions and objects present in the actual game field. The team refers to the FRC game manual to mark the dimensions for the improvised field and objects. First, the team traces the plywood with these dimensions using markers to note the part number to make assembly easier. Then, members use a circular saw or a bandsaw to cut their parts.

Once done successfully, the field border and other small components are assembled in the robotics quad and later transported to the library, where all the components are put together to produce the final product.

The team has been utilizing their access to the MAP Annex for years, marking out the perimeter with tape ensuring that their autonomous program does not cross boundaries that it is restricted.

Materials for the homemade fields are funded by corporate sponsors of the team, such as Apple, which provide educational grants. Additionally, the team allocates part of their annual budget toward purchasing materials. The team obtains their supplies and tools from Home Depot and other such stores.

Special machine training is required to operate some machinery, so veterans and parents often train newer members. There are levels of clearance for which machines members have access to and typically only team leads have full access to all machinery and equipment. The whole process is easier said than done, demanding upwards of a month to complete manufacturing and assembling the field.

“It is an intricate process because not all parts have the same strength. Some field parts have to support upwards hundreds of pounds of weight,” junior Arjun Bawa said.

Due to the fields being standardized to some extent, many parts can be reused over the years. However, Bawa said certain parts such as side walls are easily damaged and require intensive repairs, which can be an arduous task.

Senior Andrew Wu added, “The process definitely offers some educational opportunities such as teaching people some basic woodworking. Building a homemade field gives us a lot of practical life skills to take away from this, the only downside being turnaround time.”

Starting in 2026 the team will gain access to a new permanent structure, set up in the front parking lot, allowing them the space to purchase a field from the official manufacturer, which can cost over $25,000.

“This year, we want to be a robot driven team, winning more technical awards specifically when it comes to our robot’s performance in matches to complement other community and team attribute based awards,” Bawa said. “The disappointment from missing eliminations during worlds last year is the fuel that keeps us driven. Hopefully this year we can surmount those obstacles and advance further than last year.”