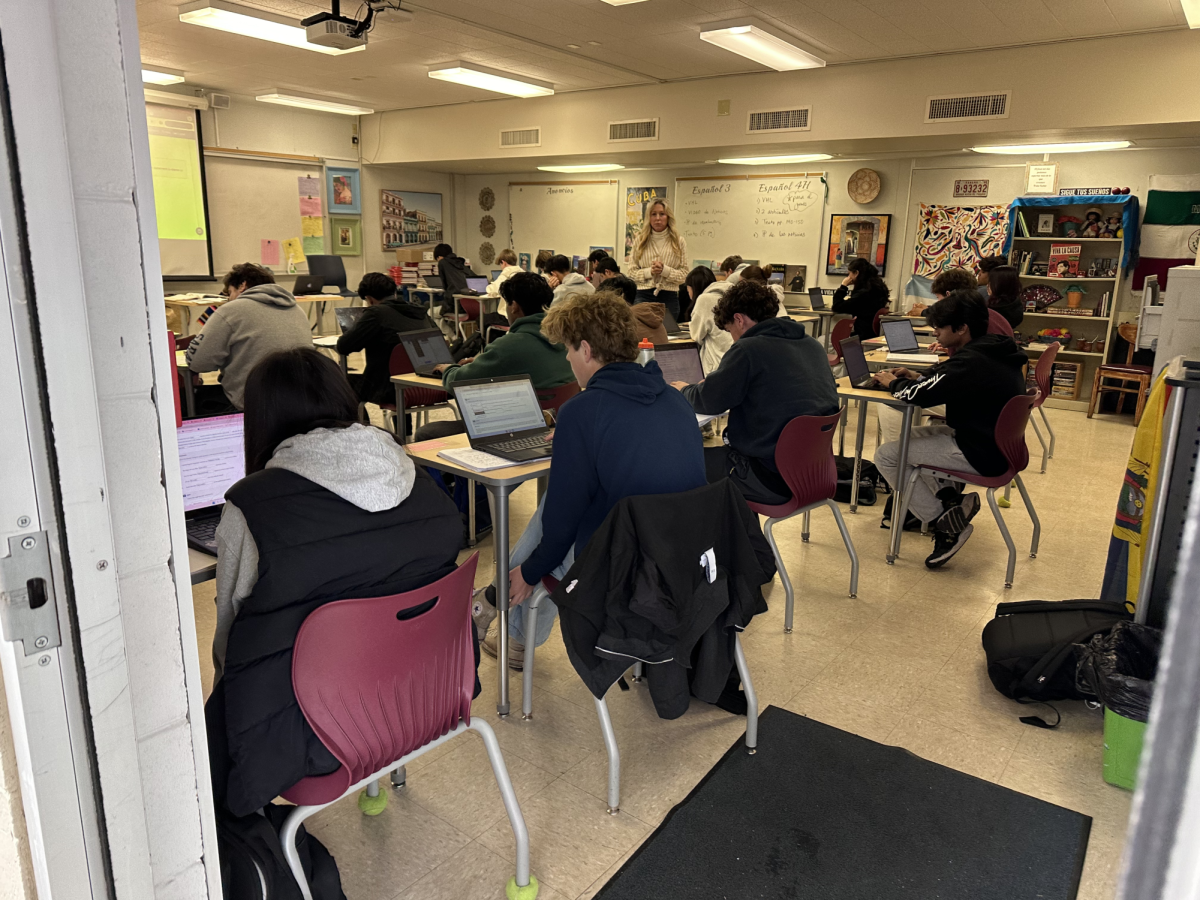

Quiet chatter and the hum of machinery filled the Engineering Lab as the 21 upperclassmen in the Engineering Design and Development class, taught by Audrey Warmuth, worked on their projects during 4th period on a recent day. Students made use of the room’s resources — VEX and Arduino parts, electronics and more — to create products of their own choosing.

This capstone project, the culmination of years of engineering electives, spans most of the school year. The class began brainstorming for their projects in November after reviewing technical skills such as working with Arduinos at the start of the fall semester. Students will continue working in groups of two to three until the end of the year.

“The project is really open-ended,” junior Luke Stratakos said. “It’s literally to do a project that you are passionate about. You set your own goals that you want to meet, and you set your own timeline.”

Stratakos is working with senior Luke Wheeler to build an industrial-size mealworm sorter. He was inspired by his mealworm farm at home, which he uses to feed his pet lizard.

Their planned design uses a motor with a crankshaft to create linear movement, Stratakos said. The mechanism will sort mealworms by size into a drawer system with bins for different size categories. Since Stratakos and Wheeler have built the sorter’s physical wooden frame, they are now working on the more technically challenging motor system by laser cutting and 3D printing pieces to fit their needs.

“Figuring out how we want to turn the rotational movement of the motor to linear motion is actually pretty challenging because we want to shape multiple buckets at the same time,” Stratakos said. “And so it’s just been hard to figure out how that’s going to work and then figure out how we can make sure it’s strong enough.”

To ensure that the motor mechanism will not break, he and Wheeler have scrounged for strong parts around the school, successfully finding a sturdy rod and a motor from an old treadmill.

Despite the technical challenges of engineering such a challenging project, Stratakos said he is having “a lot of fun” throughout the process.

“We have access to so many tools,” he said. “I think [the project] is absolutely amazing, and I love every minute of it.”

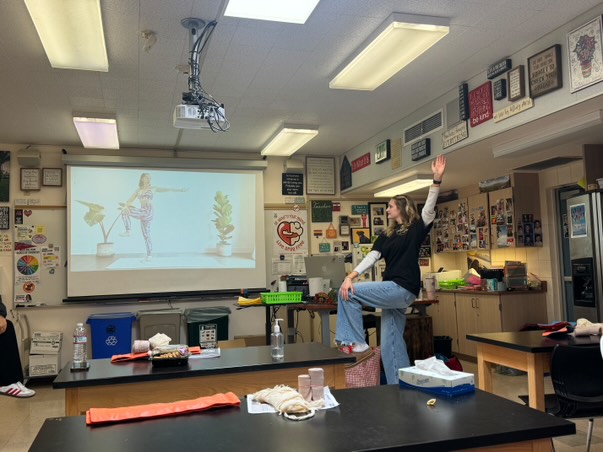

Another pair — seniors Morris Yu and Blake Zhou — is building an automatic paper airplane folder from VEX parts. Their design, based on a complex lego build Yu once saw on Youtube, uses wheels and Arduino-controlled motors to push pieces of paper through a 3-step contraption that folds the initial creases, folds the wings and then shoots the paper airplane.

“The biggest challenge is definitely maintaining the crease because when you normally fold a paper airplane, you use your thumb or your fingernail to go over the crease to make sure it stays,” Yu said. “But with VEX parts, it’s really hard to keep that crease — especially because when [the paper] is just folded, you’re not applying the pressure directly on it.”

To address this obstacle, he and Zhou plan on running the pieces of paper through another wheel mechanism, where wheel contact applies pressure to the fold, acting like a finger running over the crease.

Yu estimates that they are around halfway through the build, having completed the folding process but not the shooting mechanism. They are now fine-tuning their software for better control of motor motion by adjusting factors such as speed and amount of rotation.

Yu said he and Zhou are on track to completing their paper airplane folder. He is excited about having freedom in the class to create something of their choosing: applying skills like CAD design, mechanical engineering and digital electronics that they learned in prior engineering classes towards their own project goals.

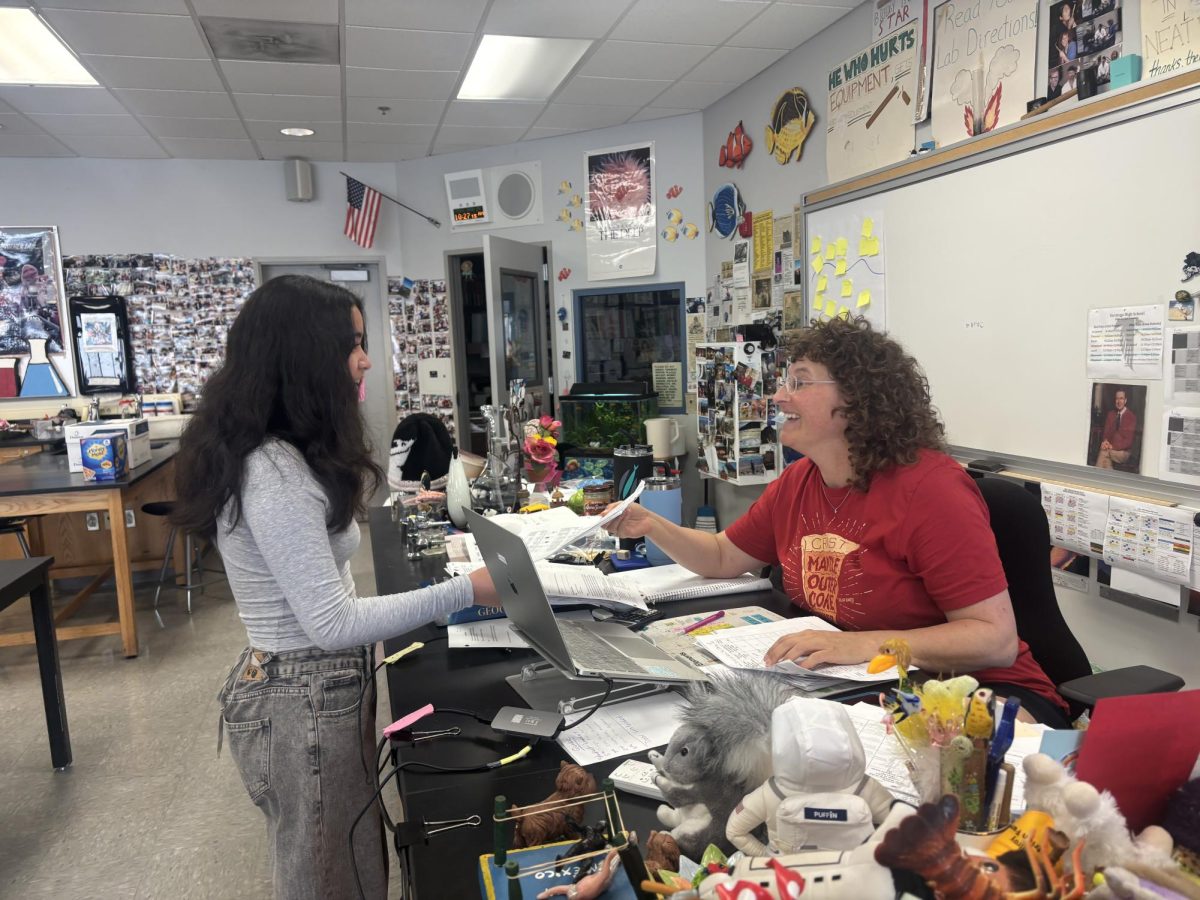

Warmuth feels that the project is an opportunity for students to practice problem-solving skills. She sees herself as more of a facilitator of the engineering process rather than a traditional teacher by providing a lab environment, tools and materials for students to use as they work independently on their projects.

Ultimately, she hopes that pushing through setbacks will give students the confidence to see themselves as builders, designers and engineers.

“I hope the kids experience the fact that engineering is a lot of trial and error,“ she said. “And then when things don’t go well, which they inevitably don’t, it’s not a big deal. The only way you get comfortable with really struggling to do something is by struggling. Then, you see it as part of the normal process.”