Introduction:

Thirty enthusiastic rookie members gathered in the robotics quad on Sept. 10, eagerly awaiting the kickoff of their robotics season. The eager newcomers appeared to be in awe of the organized chaos inside the robotics lab.

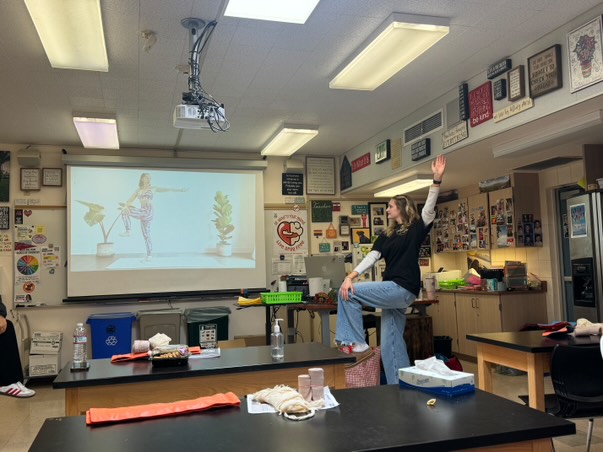

On a typical work day, Taylor Swift blasts through the in-room speaker system while the whirl of hand drills and the screech of a chop saw echoes through the room. All around, mentors stand in groups with students, some gathered near the robot to analyze the next issue to be tackled, others running the laser cutter and overseeing other machine usage. Two volunteer parents sit at the “parent table,” in charge of supervising the room for general safety and moderation of student-student interaction. The discussion taking place between students ranges from robot-related decisions to the latest AP Physics test many are stressing about.

As just a small fraction of the students who crowd Room 903 on the weekends, the rookies represented a new generation of team members within the Mechanical Science and Engineering Team Robotics Club — otherwise known as MSET — which has become one of the most popular organizations at school since its founding in 2001. Starting with less than 20 members, MSET has now grown into a community of over 100 participants across four teams.

Three of the four teams, which have 15 people each, take part in the FIRST Tech Challenge (FTC). The fourth team of 55 people competes in the FIRST Robotics competition (FRC) in the spring semester. To prepare for these competitions, which are hosted by the nonprofit organization FIRST Robotics, the teams meet up to 30 hours per week between September to April, often using the weekends for extended work time under the supervision of volunteer parents and mentors.

Club-Wide Leads:

Club Co-Presidents: seniors Nidhi Mathihalli and Trevor Leung

The Falcon observed the teams hard at work on the weekend of Sept. 10 as they went through power tool training, hardware design reviews and robot testing. Saturday was the Power Tool Lecture day, and was dedicated to familiarizing trainees with all the controls and potential hazards of the machines before they operated with them the next day.

The machines used in robotics are industry-grade tools that are very dangerous, and have the potential for injury if not used correctly. Hardware and manufacturing mentors Bob France, Mitch Lichtenberg, and Reed Kingston — parents whose students graduated from the program years ago — have created guidelines and training processes for students to abide by over the years.

FRC team 649 MSET Fish:

Team Captain: senior Nidhi Mathihalli

Hardware Lead: junior Naveed Kasnavi

Electronics Lead: junior Nikhil Mathihalli

Software Lead: junior Govind Buttar

Outreach Lead: junior Cameron Nguyen

Members of the FRC team, also known as the “Fish,” were busy preparing their robot for an off-season competition at Bellarmine Prep that occurred on Sept. 24 and 25. They were testing two different intake designs — a mechanism which takes in a ball from the ground into the shooter system — that they hoped to use on the robot.

Both intakes are about 16 inches long and made of polycarbonate. The shape is similar to two rectangles at an angle of approximately 135 degrees, spaced apart with axles and squishy wheels running across them. After prototyping during the competitive season, the team found the squishy wheels to get the best grip on the large, tennis-ball like game pieces.

The first intake design was a modification of their original, and was being implemented directly onto the robot for the first competition. Meanwhile, other hardware team members worked on a completely new design that was more durable, which they hoped to use for another competition in October. The new design transferred power from the motors to the axles with gears, which were mounted on the outsides of the polycarbonate plates.

The prototype intake design was being tested by a few members of the software team, who were mainly focused on its folding and deployment. The new design uses a motor to power the deploy, replacing the old pistons.

Other members of the software team were working with the main robot and testing the shooter at various distances from the goal, which they housed in the MAP Annex due to its size. Both days of the weekend were spent doing such software testing.

On Sunday, the FRC team also held an outreach meeting, where they discussed all the initiatives and projects they were currently working on to spread STEM and robotics awareness throughout the community.

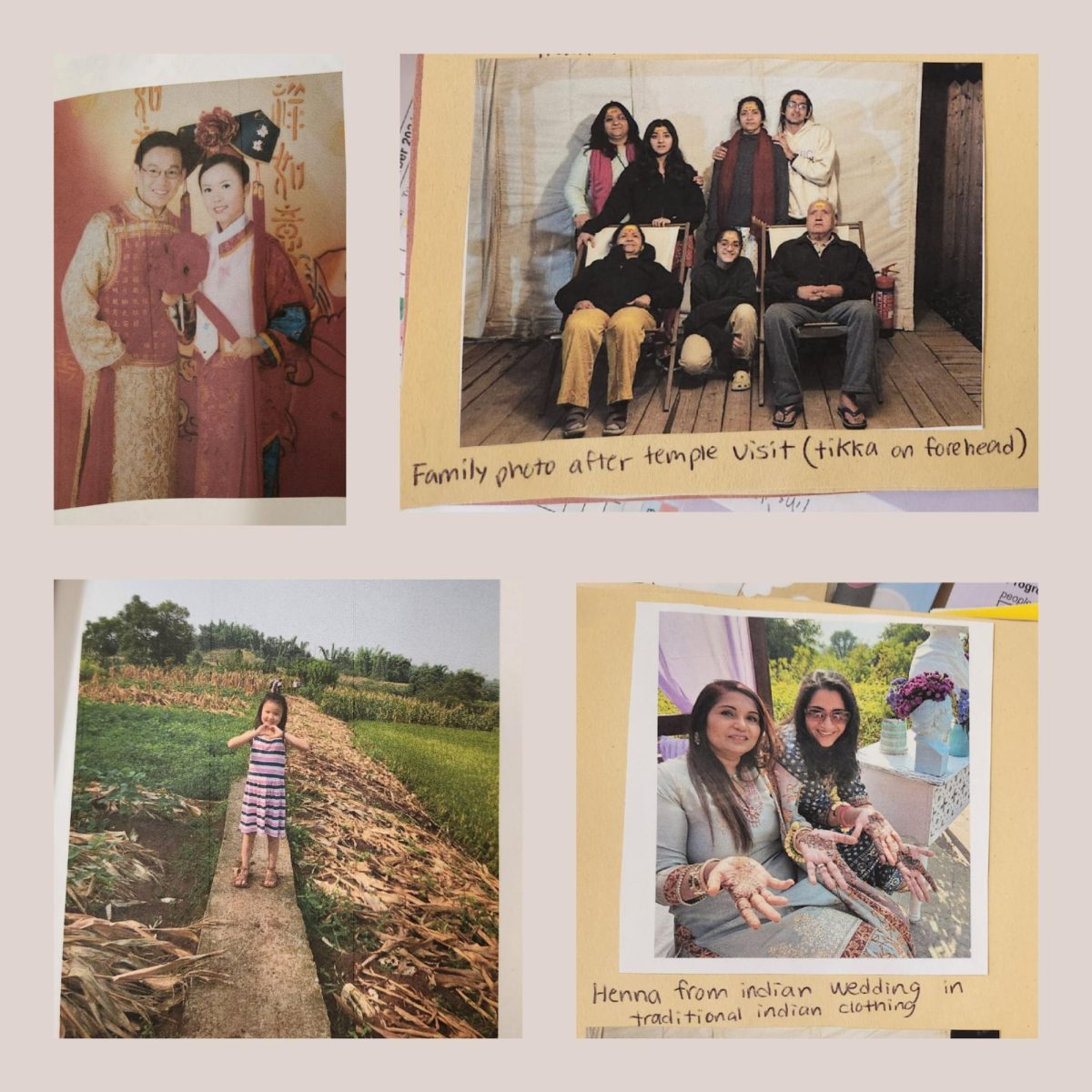

Some of the projects they discussed included GoBabyGo, where students modify ride-on cars to aid children with mobility disabilities, and Vikalp Sansthan, an organization where the teams create English and math videos to teach girls in India who don’t have access to education.

Though a task is often assigned to one person, all team members of both FRC and FTC constantly collaborate with each other during a build session. Many members have found that it increases productivity and allows the team to create more ambitious goals.

“When I get to a build session, I first identify what my task is for the day and what I’m supposed to be working on,” said sophomore and FRC hardware member Richard Chung. “If there’s ever a problem, I work with different teammates to come up with a solution, and run it by the leads to get their input. Working with my teammates ensures that an idea is really solid and has been fully thought through.”

FTC team 6165 MSET Cuttlefish:

Team Captain: senior Trevor Leung

Hardware Lead: senior Emily Lu

Software Lead: senior Matthew Song

Management Lead: senior Apoorva Talwalkar

The FTC teams spent their Saturday attending the season kickoff event on Sept. 10. Once their game challenge had been revealed, they began designing their robots.

They held strategy meetings in the afternoon to discuss the fine details of the game and scoring, as well as the capabilities they wanted to eventually design their robot for.

The FTC teams also hold weekly “org” (or organizational) meetings on Sundays, where mentors for each team sit down with all the members and address their management, hardware, software and outreach progress.

Leung said he believes organizational meetings help the team stay on track with their goals, since there are so many tasks that need to be completed at any point during the robot preparation.

FTC teams 7390 MSET Jellyfish and 7641 MSET Bettafish:

Jellyfish Hardware Lead: sophomore Asheeka Noronha

Jellyfish Software Lead: junior Brad Ma

Jellyfish Management Lead: sophomore Anusha Guha

Bettafish Hardware Lead: sophomore Ethan Yang

Bettafish Software Lead: sophomore Aadit Noronha

Bettafish Management Lead: freshman Arusha Suvarna

Two of the FTC teams in MSET, the Jellyfish and Bettafish, are composed primarily of rookie members and rely on the guidance of their veteran Cuttlefish members during and after the kickoff.

A few Cuttlefish members held a meeting with the Jellyfish and Bettafish that Sunday to discuss the game in more depth and guide them on how to approach the first few days of the season.

The discussion was similar to the one that took place among the Cuttlefish the day before, where they studied the 80-page rule book and answered any questions members might have regarding the gameplay.

“The first 72 hours after kickoff are super critical,” senior Cuttlefish management lead Apoorva Talwalkar said. “The game and rules are still fresh in everyone’s mind, and it is important to set the groundwork that the team can go off of for the rest of the season. The team also gets the opportunity to bond and know each other better before the rush of the build starts.”

The Bettafish and Jellyfish then participated in a general design meeting with a couple hardware mentors, while the Cuttlefish began discussing the finer details of their design plan.

“Working on the weekends gives us longer periods of uninterrupted time, and people are generally less busy,” junior FRC member Owen Liang said. “The mentors are also available on the weekends, and it makes everyone a lot more productive to have help and someone to bounce ideas off of.”

As they gear up for the upcoming seasons, all four robotics teams will continue to meet regularly. The goal of all these hours of collaboration, of course, is to complete the robots as quickly and effectively as possible.

“There is a lot of potential on all the teams this season,” Leung said. “We have established leadership and schedules for the teams, and I’m really excited to see how far they can all go.”