On any given night, senior Asheeka Noronha can be found sitting on her bedroom floor, blasting Steve Lacy music and carefully assembling different parts together to create 3D printed hands or arms.

Noronha is one of 14 members on FTC team 6165 MSET Cuttlefish certified to build prosthetic hands through e-NABLE, an online community who uses their 3D printers to manufacture low-cost prosthetic upper limbs for children and adults in Uganda, Brazil and Tanzania.

The initiative was brought to the team three years ago by Class of ‘23 alumnus Trevor Leung, when the team’s mentor, Anh-Quan Thinh Nguyen, stumbled upon the e-NABLE website after reading a robotics article online.

In the past two years, one or two members on the team were certified from e-NABLE to make prosthetics, and the team only made two or three devices per year. This year, however, the team’s e-NABLE lead, junior Lucius Ko, has supercharged those efforts and gathered over 800 prosthetic hand cases for his team members and collaborators worldwide.

So far this year, 26 hands have been shipped out. Although the Cuttlefish have been working on these orders for months, it takes many hours to make these prosthetics. Each one requires at least two days to plan using Computer Aided Design (CAD) software, 3D-print and build.

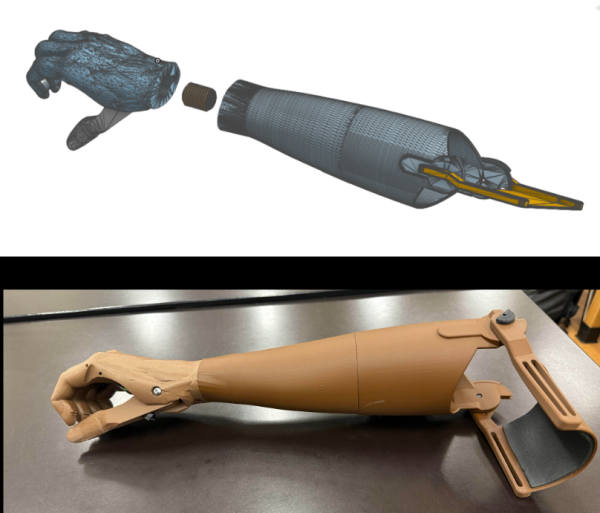

In order to build a low-cost prosthetic hand, members adjust a template CAD for each client’s measurements. Then, members print the parts in one of six 3D printers that Cuttlefish students and mentors own. Finally, the members follow a quick tutorial to assemble the hands and possibly string, depending on the hand type.

Cuttlefish reaches out to the World Action Fund in Uganda to find more people in need of prosthetics

More than a year ago, Noronha decided to search for more cases through the e-NABLE website. In August, she enlisted the help of Riyan Zahid, a junior at Dakota Collegiate, a public high school in Winnipeg, Canada, who runs the e-NABLE Winnipeg chapter.

Zahid was working with Peter Odoma, the founder of the World Action Fund (WAF) in Uganda, and he introduced the organization to the Cuttlefish. Eventually, WAF and Cuttlefish collaborated to create the Uganda e-NABLE Coalition in January, a new branch dedicated to prosthetic cases found in Uganda.

Almost 49 million people live in Uganda, and among those over 42% of the population lives in poverty, described as making less than $2.15 daily in the United States. Adding to the people’s difficulties, the country is also now under the authoritarian regime of Yoweri Museveni.

Political parties were banned from 1986 to 2006, and critics say Museveni has used legal means, patronage and violence to maintain his dictatorship. Uganda has had a history of corrupt leaders, such as Idi Amin, the dictator who ruled Uganda from 1971 to 1979. Amin was notorious for widespread human rights abuses, violent purges and economic problems.

Amid the challenging conditions, Odoma initially found 373 prosthetic arm cases, mostly from individual incidents such as farming or other work-related accidents as well as birth defects.

Eyotre Rhony’s upper limb amputation

Among the cases Odoma found was an adult man named Eyotre Rhony, who was located in a city in Uganda’s West Nile sub-region, Arua. Rhony was a farmer who cultivated cassava, groundnuts and maize, providing for his family through hard work and determination. Because of this, farming was not just his livelihood; it was his identity.

The night his life changed forever was supposed to be like any other. Rhony, 36, had just finished his evening meal in late 2020 and was preparing to settle down for the night when a gang of armed thieves, desperate and ruthless, stormed into his home. Rhony fought back and sustained a brutal injury that resulted in his left hand being severed.

The attack changed his life forever. Without the use of only his right arm, he could not till the land, carry water and even feed his animals.

“When I lost my hand, I thought my life was over. I couldn’t farm, I couldn’t work — I felt useless,” Rhony told Odoma.

This past November, Rhony learned about the World Action Fund from other villagers. The organization was conducting assessments for people with upper limb amputations in Ajia, a nearby rural village.

A few days later, a team from WAF arrived at his home on motorbikes. Under the shade of a broad mango tree, a small wooden chair had been placed for them. Rhony, though reserved at first, welcomed them warmly.

As they examined his condition, Rhony listened, learning about prosthetic hands and about the possibility of regaining some function. He agreed to try it.

In early January, a prosthetic made by Ko arrived at his home.

But for Rhony it was never just about regaining his hand, it was about reclaiming his dignity, his ability to work and his sense of self-worth. For the first time since the attack, Rhony said he felt something shift within him because of the new prosthetic. The wounds of the past could never fully disappear. He realized that his future was not lost. And so, under the mango tree, hope was planted once again.

“At first, I doubted if I could ever use this prosthetic,” he told Odoma. “But when I held a hoe again, something inside me came back to life. I am a farmer once more. This arm is not just plastic and metal, it is freedom. I can feed my animals, I can write my name, and I can work again. I never thought this would be possible.”

Rhony rebuilds life with a new purpose

At first, using the prosthetic was challenging for Rhony, but with training and perseverance, he has adapted. Slowly, he has regained his ability to perform basic tasks such as holding a hoe, carrying produce, writing his name again and making phone calls while holding the phone with the prosthetic hand.

With his newfound independence, Rhony has also decided to diversify his work. In addition to farming, he ventured into beekeeping, an activity that required less physical strain but offered financial rewards. He started with a few beehives, learning how to manage them with his prosthetic hand. Over time, he became skilled at harvesting honey and selling it in local markets. His honey business flourished, and soon, he was not only supporting his family but also inspiring others with disabilities in his community.

Through resilience and the right support, Rhony transformed his personal tragedy into a new beginning.

“Many people with disabilities are hidden away, but I want them to see me and know that life does not end with an amputation. There is always a way forward. They restored my dignity. Now, when I wake up in the morning, I don’t see loss—I see opportunity,” Rhony told Odoma.

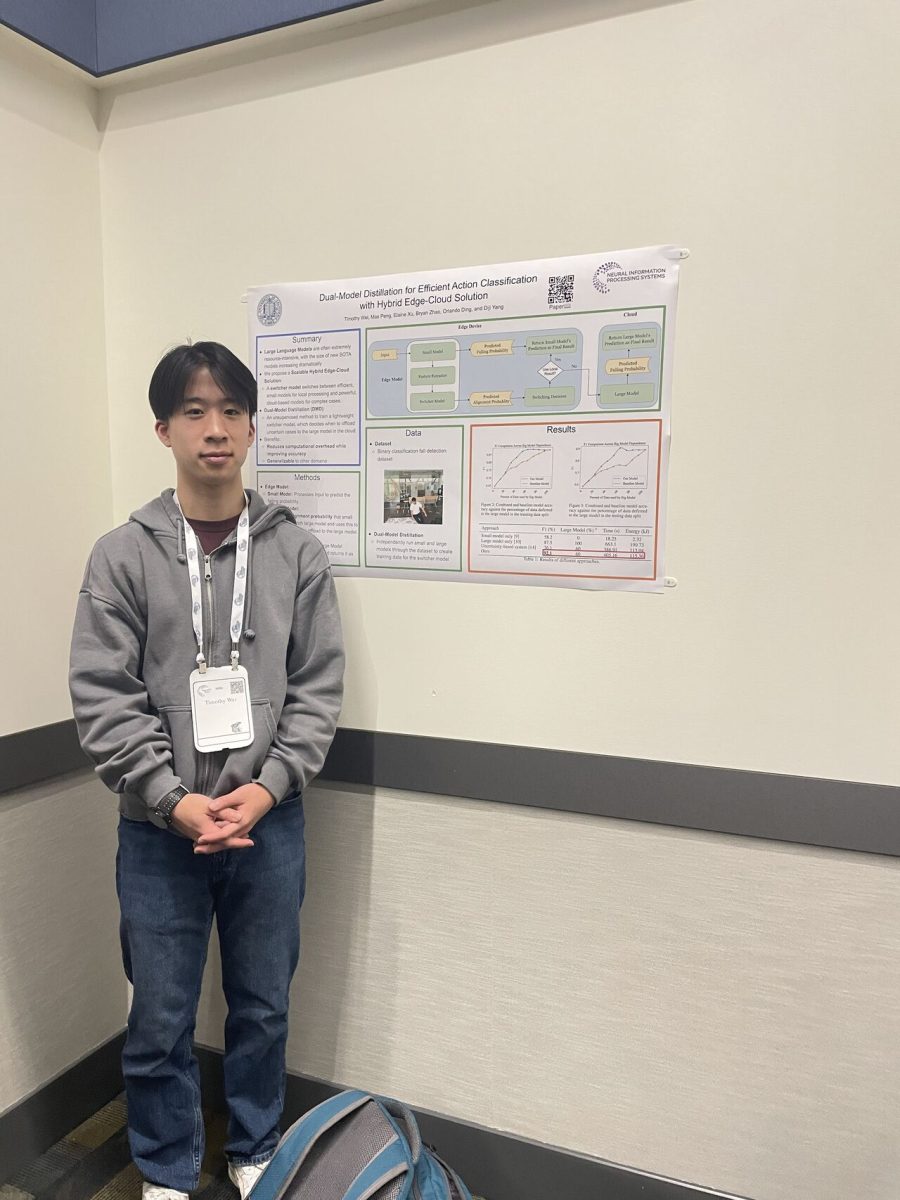

Eyotre Rhony, a Ugandan who lost his arm in a theft, receives an Unlimbited Hand made by junior Lucius Ko.

Inspired by Rhony’s renewed lease on life, Odoma tried to expand his efforts in February by reaching out to a hospital in Uganda that houses wounded victims of the Lord’s Resistance Army.

The Lord’s Resistance Army, a Christian extremist organization localized in Central and Eastern Africa, has been known to mutilate civilians by cutting off their hands as a brutal tactic to weaken the government and prevent people from serving in the military. Some of these victims were receiving care from the hospital that Odoma’s team reached out to, and they found so many people that needed prosthetics that their number of target cases increased from 300 to over 800 cases throughout the months as Odoma got more familiar with the hospital.

Team improves hand design and shipment based on client feedback

As the number of cases grew, Ko and Noronha realized they had to speak to professionals for advice on how to maintain quality while producing a larger number of orders. Through Nguyen’s connections, they met with an engineer named Eamon O’Brien, who runs the nonprofit Kyaro Assistive Tech in Tanzania. O’Brien creates wheelchairs that can be used on the hundreds of unpaved roads in the country.

Through a couple of meetings with O’Brien, the team learned methods and tricks for creating assistive technology. They learned to ask for feedback from the client, which ultimately helped them refine the process and choose a better prosthetic design.

“So when we asked Odoma what people wanted, we started to realize that he was more interested in the aesthetics of the prosthetic rather than the functionality,” Noronha said. “It’s something we were super surprised by because here in the U.S, the stigma is not nearly as large around people with limb differences; we were missing the perspective of a Ugandan citizen with a limb difference.”

Initially the members were creating Unlimbited Hands, which were one of the easiest models to assemble and create with CAD. But they soon realized that it would not be the best option for aesthetics or even functionality. The Unlimbited Hand was notably weak at gripping objects and couldn’t even lift a water bottle, which was inconvenient because most clients are farmers. In order to grip objects, the client had to keep their elbow in place.

While talking to Odoma and his team, junior Eric Woo-Shem, the team’s research and development lead, realized that the people needed an arm that was easy to move while having a strong grip strength.

When searching for solutions in early February, he and Ko came across many different device designs that e-NABLE offered including the “Kinetic” hand and the “Kwawu” arm. Even though they looked similar to a normal hand, their grip strength was also not very functional and both hands were also extremely fragile. After talking to the founder of e-NABLE, Jon Schull, Woo-Shem and Ko found a CAD of the “Gripper” hand — a simple, realistic-looking device with an incredibly strong grip.

However, there was still the issue of finding a way to attach a realistic forearm onto this hand. By revisiting the “Kwawu” arm, Woo-Shem created a prototype of a final arm by using the forearm of Kwawu and the hand of a Gripper. This combination — with a few optimizations — had a vastly stronger grip while still being easy to reproduce. In order to further improve the grip strength, they coated the fingers of their prototype with a layer of silicon so it would produce greater friction when holding objects.

Ko’s CAD and assembly of the new hand designed by junior Eric Woo-Shem, using the Kwawu arm forearm and Gripper Hand optimize functionality.

As the Cuttlefish team built hands for more and more clients, they not only received feedback on hand functionality, but also the best shipping methods. Some clients informed the team that there were issues with shipping, where some hands were disassembling in the process, with the forearm bending or stringing of the actuators becoming loose. And if the hands were deformed during shipping, it was difficult, if not impossible, to put it on someone’s arm.

So, Ko assigned sophomore Maxwell Tham, a member of the software team, to be in charge of quality assurance for all hands they build. Tham compiled all the client feedback and summarized it on a Google document so other team members could see it and make improvements to their own arms.

Tham also overlooks all assemblies, analyzing the products to make sure they are as good as they can be before being sent. For example, many clients said the Velcro that goes around the forearm was too tight, causing pain for their stump, so now Tham checks to make sure the Velcro is as loose as possible before shipping. Recent shipments have also included prosthetic socks to cushion the client’s arm stump as well as pool noodle segments, which can be attached to grip cylindrical shapes objects such as brooms.

Cuttlefish reaches out to local community to fund initiative

While quality assurance and general feedback were being taken care of by Tham and Woo-Shem, there was still a growing concern of the funding.

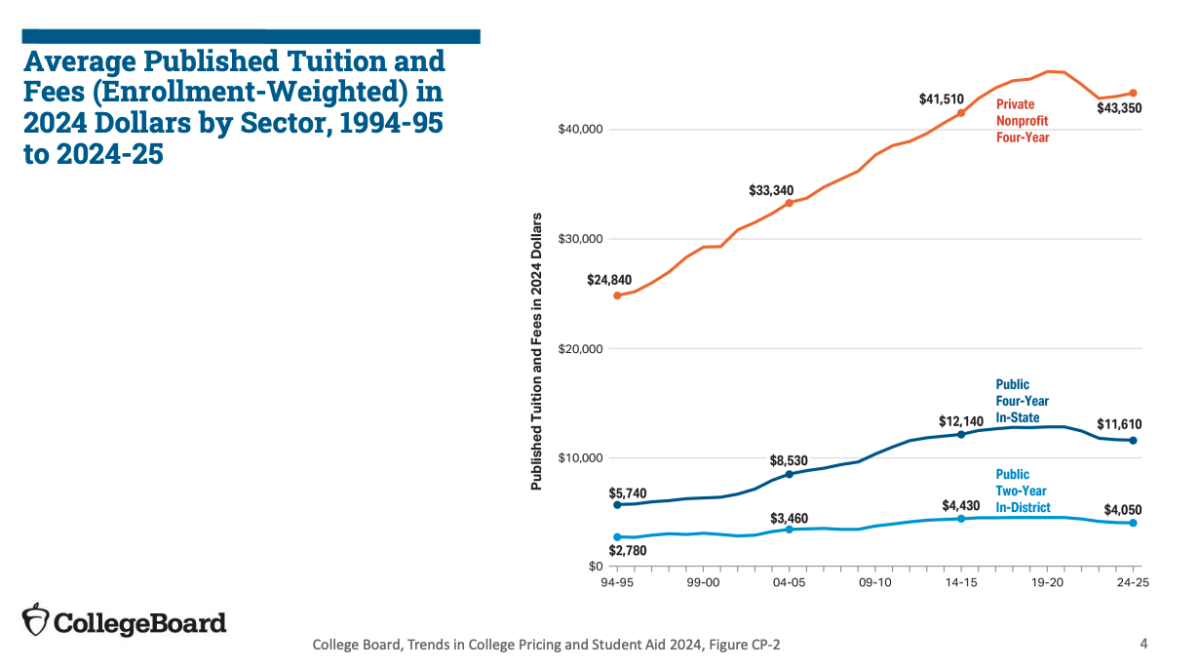

The Uganda e-NABLE Coalition now estimates it will take $35,000 to fulfill all of the orders they have for the Cuttlefish, a cost that includes raw materials, measuring the clients, transportation and shipping costs.

The Cuttlefish decided to help out the coalition by fundraising locally, through a gofundme, corporate matching and private donors. In the past month, they have raised over $12,000 for the coalition. On March 28, they are hosting a fundraising dinner at Hong’s Gourmet downtown Saratoga with admission prices of $50 to increase awareness of the outreach initiative and raise more money for it.

Moving forward, the Cuttlefish are looking to expand the initiative even further by seeking new members. The Uganda e-NABLE Coalition is recruiting members to assist in prosthetic production. To join, anyone can send an email to [email protected] or join the Facebook chapter. The Cuttlefish also host an e-NABLE club at school, where anyone in the school can assist with making the prosthetics, which meets every Blue Monday and Tuesday.

Schull, the CEO of e-Nable, said, “[The Cuttlefish] remind me that it really is possible that a global network of volunteers can, in fact, make a real difference and fill the gaps that governments and businesses and enterprises fail to do.”