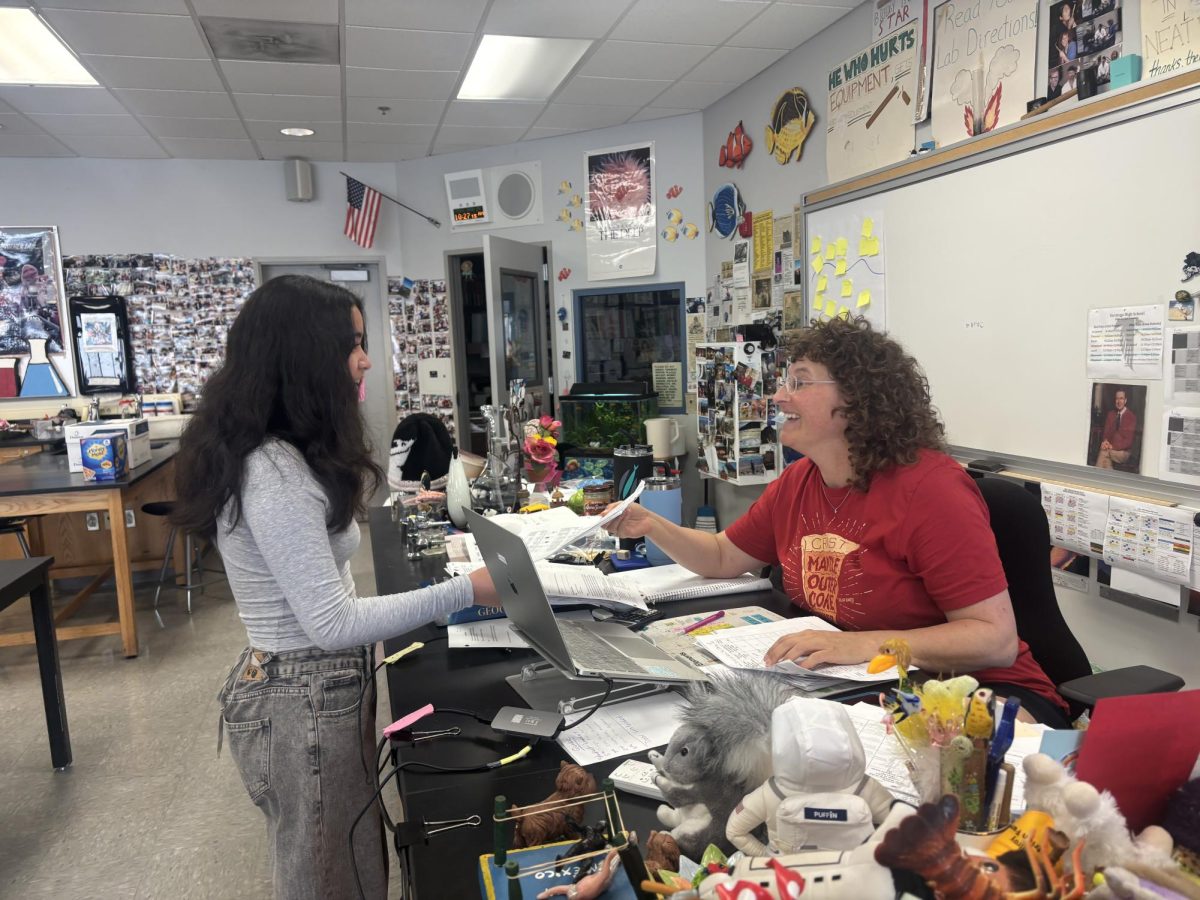

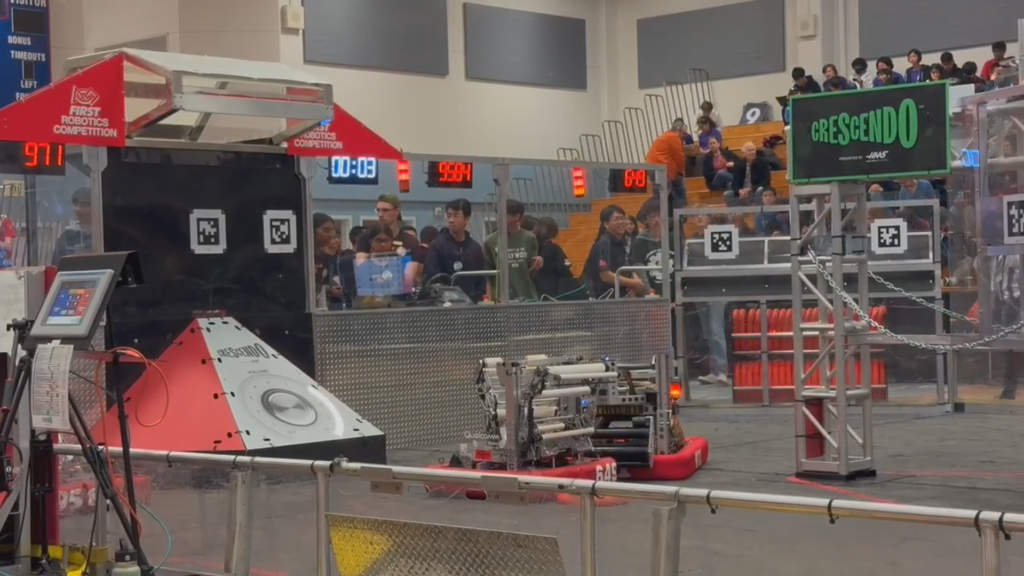

The night before April 13, when the MSET FRC team’s robot was due to be shipped off to World Championships in Houston, numerous students and mentors watched the robot drive across the library’s full-length field — the size of half a basketball court — a structure made of wood and sectioned off with black tape. As soon as the drivers let go of the joysticks, students jumped onto the field to fix the robot in preparation for the last event of the season.

For the third year in a row, the team traveled to the Houston World Championships and competed with one of their most technically complex robots ever. Here’s how they got there:

- March 7-10: San Francisco Regional

- Seeded sixth of 43 teams

- Won the Team Sustainability Award

- March 27-30: Monterey Bay Regional

- Seeded 27th of 37 teams

- Won the Regional Impact Award, and qualified for the World Championship competition in Houston, from April 17-20.

- April 4-7: East Bay Regional

- Seeded 13th of 61 teams

- April 17-20: Daly Division of World Championships

- Seeded 40th of 75 teams

The team won the Team Sustainability Award for members’ efforts in long-term continuity and Regional Impact Award for both their national and international outreach. This year is also their first in their 20-year history to compete in more than two regionals. Nevertheless, the team maintained their energy throughout the two months of competition with more than half the team cheering from the stands while the student “drive team” drove the robot across the field.

Courtesy of Ameya Saund

“[Being in the stands is] stressful, a lot of it. People [on the team] constantly look [at our robot] to see if there’s an issue, but that makes the joy from seeing our work properly so much better,” Belenje said. “I don’t think others do this as much, but I love just yelling random stuff, and we all cheer when we score — it’s pretty exciting, like a culmination of [our] work.”

Before their first regional — where the greatest percentage of the team was present at the competition since the start of the COVID-19 pandemic — the team pulled a competitive robot together, through the efforts of new and experienced members alike.

Despite several setbacks before the competition that left the team finishing the robot even later than in previous years, the team still had a robot ready for their earliest season competition since 2016.

“It’s been cool to see underclassmen caring more about the team’s success, especially with how good we look this year, and I think people feel more attached to the team,” Belenje said.

The team had been planning since the offseason to expedite their build season — the six weeks reserved for building a robot from the ground up before competitions kick off. To allocate more time for the software team to test the robot, the hardware, manufacturing and electronics teams needed to be much more efficient.

The hardware team planned to spend less time on CAD (Computer-aided Design), while the manufacturing team quadrupled in size from the previous year; but within four weeks of following through with the target timeline, progress began to stall, and those changes didn’t help as much as expected.

According to senior Owen Liang, a member of the hardware team, the lack of experience from the underclassmen-dominated group prevented them from keeping up with the ambitious CAD schedule. The manufacturing team fell behind in making parts because of overreliance on the inexperienced manufacturing team, rather than expert adult mentors. The electronics team was backlogged by ineffective communication and the members’ busy schedules.

But at that point, it was clear the team had a plethora of items to improve upon before the World Championships. Over the course of the next month, they added new autonomous paths where the robot can score more during the first 15 seconds of the match where the robot moves autonomously, increased shooter accuracy, and built a mechanism so that the robot could climb on a chain for the last portion of the match called “endgame.”

In Houston, the team played in the Daly Division, but did not make it to the playoffs primarily because their elevator — a central mechanism in the robot — broke during a practice match. Despite not making it to the elimination round, during their last qualification match of the entire season, the team played a high-scoring match that demonstrated the season’s work toward creating a far-shooting and agile robot. They were not picked to play in the elimination round and enjoyed the rest of the competition watching the best teams in the world compete.

“It was unfortunate that the elevator broke and took out half the robot’s functions with it before matches even started, especially given that it was the last comp for a lot of the members [as seniors],” Liang said. “I think we did pretty well given what happened, though, and everything else held up pretty well.”